DESIGN

Rugged Electronic Design Capabilities

From enclosures to circuit boards and embedded code—every detail is engineered in-house for complete control and performance

ENGINEERING EXPERTISE

With a suite of the most innovative tools such as Altium, AutoCAD, and Aegis, our team pushes the boundaries of MIL-Spec designs.

MODULAR DESIGN APPROACH

We streamline product development by leveraging 30 years of design experience and a wide catalog of proven sub assemblies.

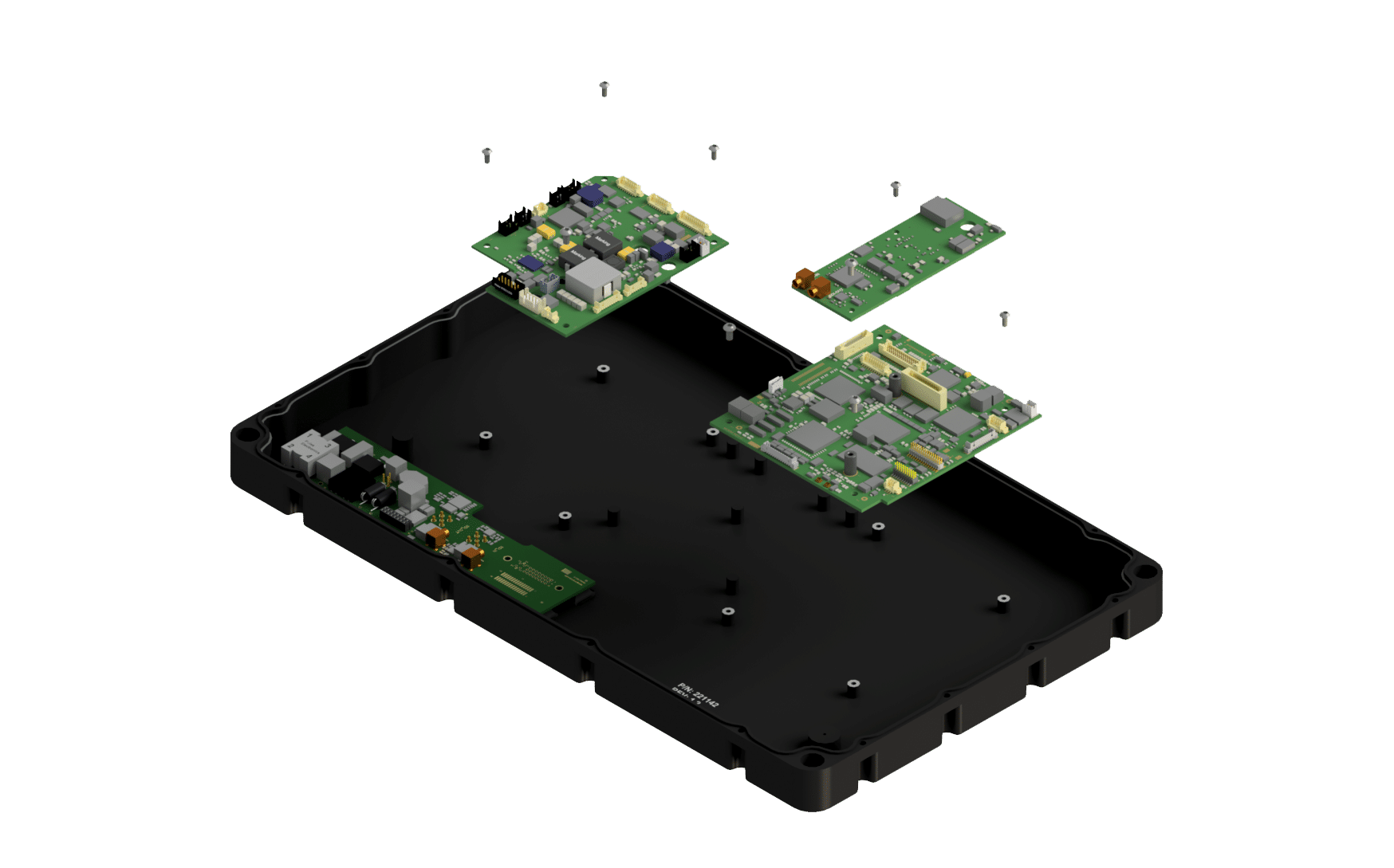

DESIGN-BUILD MANUFACTURER

As a vertically integrated design-build manufacturer, we are uniquely positioned to deliver efficiency and flexibility while creating products.

Engineering Expertise

Our skilled engineering team encompasses a wide variety of disciplines, including mechanical engineering, software engineering, and electrical engineering. With an average of +25 years of experience in their respective fields, our team members are committed to developing cutting edge solutions to industry needs, while pushing the boundaries of innovation. This collective, in-house expertise enables us to efficiently design rugged solutions to meet our clients’ needs.

Mechanical Engineering

DSE’s in-house mechanical engineering team designs rugged electronics and user interfaces tailored to mission-specific needs. Using milled aluminum housings, our solutions efficiently adapt to changing I/Os, subassemblies and installations. From product ergonomics to man-machine interface to mechanical adaptations, every design is built for flexibility, durability and seamless integration.

Key design areas:

- Milled Aluminum Enclosures

- User Controls

- Touch Screens

- Interface Connections

- Ergonomics

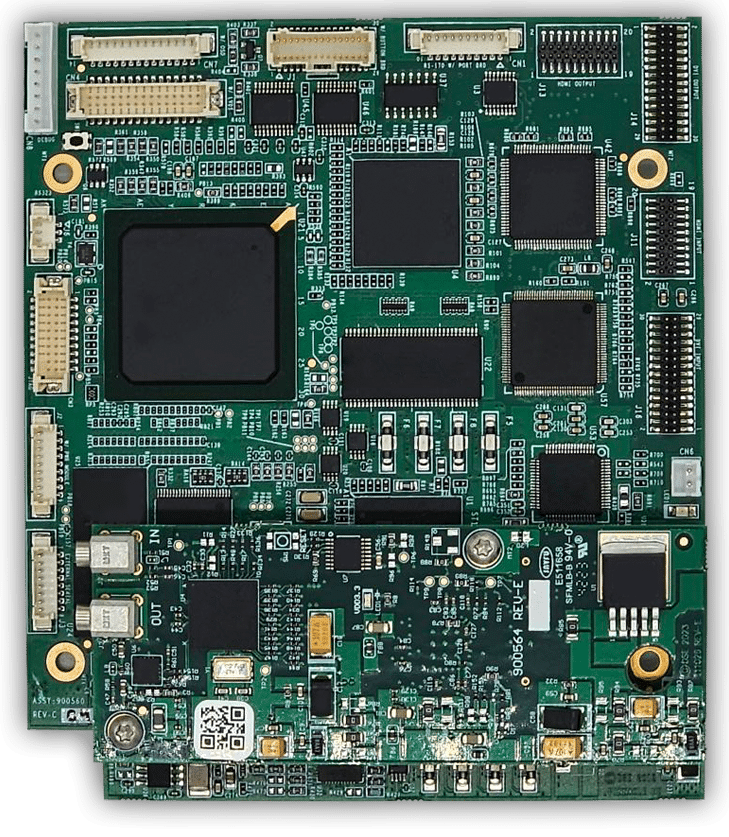

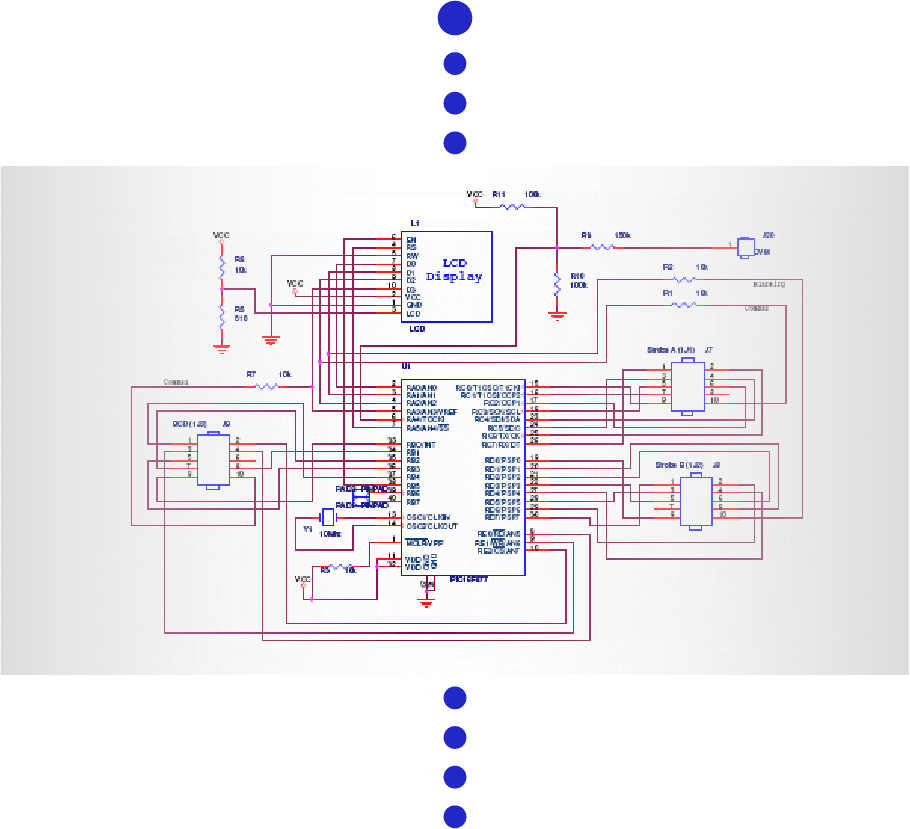

Electrical Engineering

Electrical engineering at DSE begins and ends with creative problem-solving. Our team bridges concept and production by leveraging decades of experience and a robust library of proven designs. Complex video processing, protocol conversions, power generation and distribution are just some of the areas our team focuses. DSE owns the PCB designs and can quickly pivot to address application specific requirements.

Key design areas:

- Video Processing

- Signal Conversion

- Custom Signal Mapping

- MIL-STD Compliance

- Power Regulation

Software Engineering

DSE’s software team develops the intuitive interfaces that unify our rugged hardware components into mission-ready systems. From on-screen menus and overlays to control protocols and custom embedded features, we develop reliable top-level products that perform with precision in demanding environments.

Key design areas:

- User Interface

- Control/Command Protocols

- On-Screen Menus

- Custom Interfaces

- Video Processing

Modular Design Approach

Our modular design approach leverages 30 years of rugged design experience and a wide catalog of proven components and products

Our Design Process:

DESIGN

We begin our design phase with a consultative approach, working closely with our customers to define program specifications. Our team analyzes these requirements against our existing product lines and proven components to determine the scope of development needed. This modular approach, as well as DSE’s in-house manufacturing capabilities enable us to secure competitive rates for custom and small run production. Key documents, including development schedules, interface drawings and three-dimensional models are then shared with our partners before moving to production.

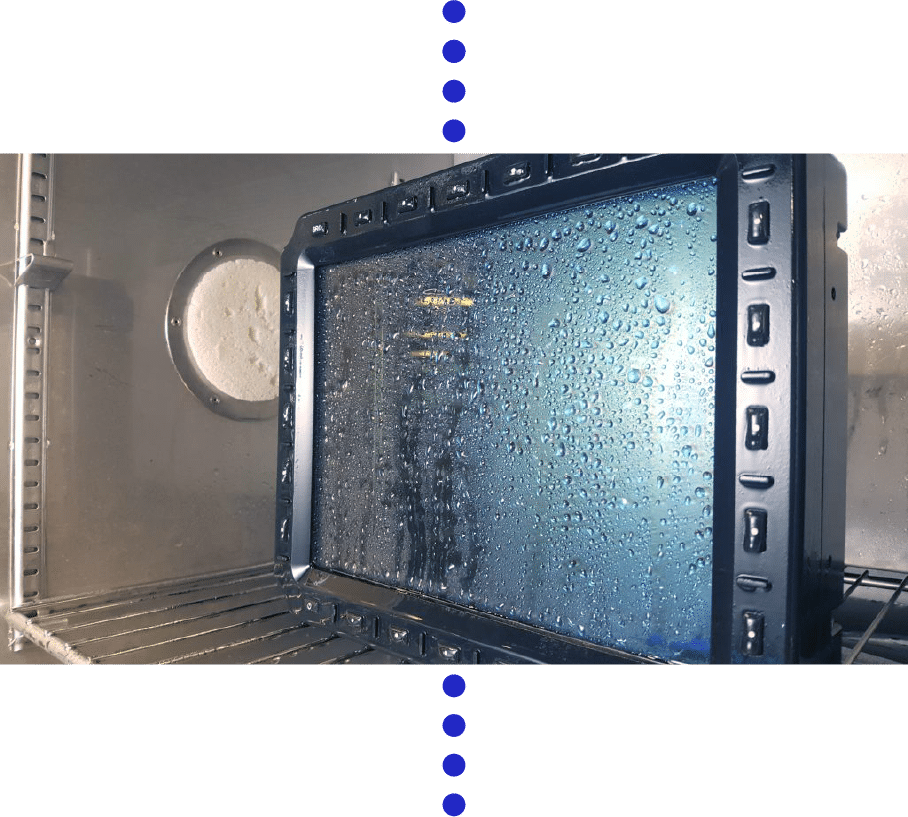

VALIDATION

As the development process continues, DSE’s engineering teams meet regularly with clients to review progress and program requirements. Our “all hands” approach ensures products move smoothly from specification to production of first article units. Next, DSE employs a series of environmental validation and general acceptance test procedures. In-house testing capabilities for vibration, temperature, submersion and more ensure this stage is handled with accuracy and expediency.

SERIAL PRODUCTION

After the initial delivery of prototype units, DSE commits to providing ongoing support throughout the program's lifecycle. This includes overseeing sub-assembly inventory, managing product life cycles, maintaining revision control, and ensuring the effectiveness of processes such as assembly instructions, Acceptance Test Procedures and equipment calibration. This effort sets the foundation for consistent, repeatable product manufacturing before serial production even begins.

Learn how DSE develops custom solutions, from specification to production

In-House Design-Build Manufacturer

DSE implements a strategic, vertically-integrated method to designing and manufacturing rugged electronics, overseeing every stage of development to streamline assembly and ensure adherence to standards.. With in-house capabilities covering engineering, design, sourcing, manufacturing, and validation, DSE emphasizes agility, innovation, efficiency, and quality for clients.