About Digital Systems Engineering

Since 1995, Digital Systems Engineering (DSE) has achieved a worldwide reputation for excellence in the design and manufacture of leading-edge rugged electronics. Specializing in ruggedized, flat-panel LCD displays, advanced video image processing technologies such as HDMI, SDI, DVI-D and rugged computing, DSE’s outstanding team of electrical, mechanical and software engineers provide customized design and manufacturing services to military forces, prime contractors and commercial sectors worldwide.

Headquartered in Scottsdale, Arizona, DSE is a small business that is proud to design and manufacture its products in the USA.

Custom Solutions

DSE is a design-build manufacturer with expertise in developing custom solutions

Quality Assurance

As an ISO9001/AS9100 registered company, DSE takes pride in delivering a high level of quality and exceeding expectations

Engineering Expertise

With a core competency in design engineering, each of DSE's engineering team members brings an average of 25+ years of experience to the table.

Extensive Catalog

DSE’s deep product line is the result of decades of engineering development and includes hundreds of COTS solutions

250+

Unique applications from aerospace to mining

500

Distinct products developed by DSE

30,000+

Installations across the globe

100+ M

Operational hours in rugged environments

A Vertically Integrated Design-Build Manufacturer

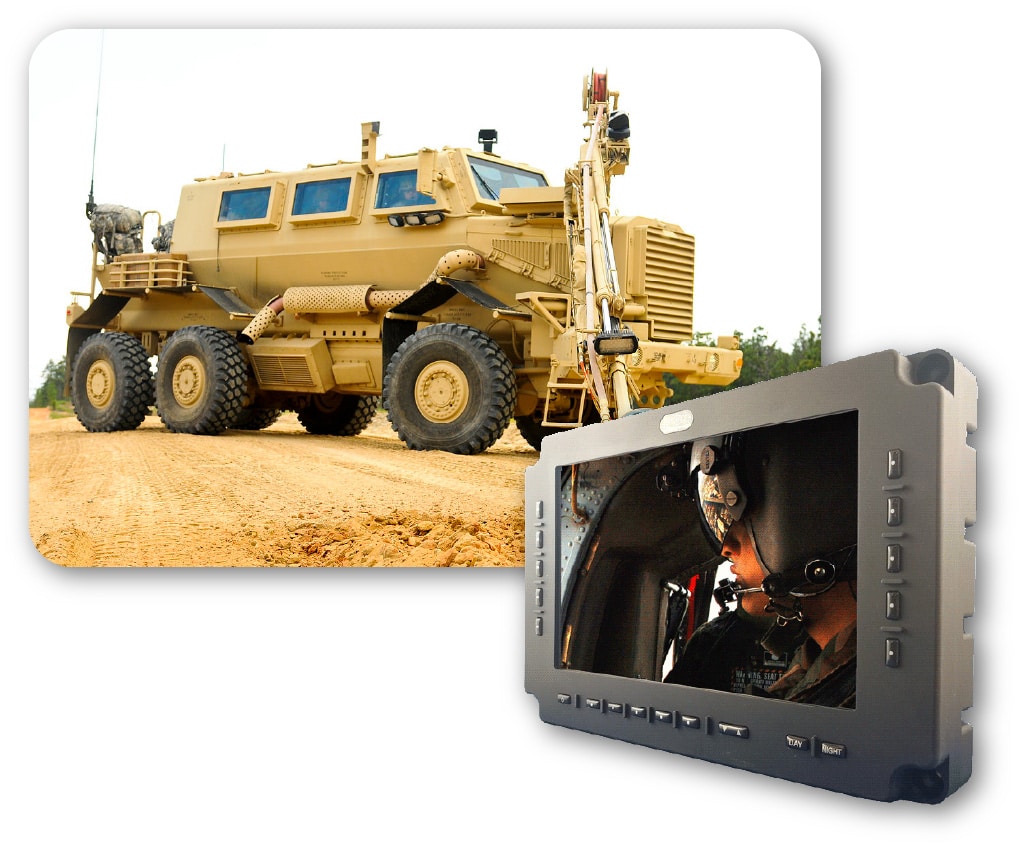

DSE takes pride in a strategic, vertically-integrated approach to designing and manufacturing advanced rugged electronics. By overseeing every stage of product development, from concept to production, DSE is able to streamline the assembly process and ensure each component adheres to design and performance standards as well as customer functional requirements. With in-house capabilities spanning engineering and design, material sourcing, manufacturing and product validation, we have the agility to meet unique program specifications and needs. This comprehensive approach underscores our dedication to delivering innovation, efficiency and quality to our partners.

Our Team

DSE was founded in 1995 by two engineers with a passion for solving problems. Today, DSE’s full staff of dedicated team members combines expertise in engineering, design, customer success and more.

Rick Ridley

Founder, CEO, President

Erik Copeland

COO, VP Engineering

Ross Hudman

VP, Sales & Marketing

OUR MISSION

To create exceptional value for our customers, vendors, employees and shareholders through mutually beneficial relationships that foster and reward honesty, integrity and hard work.

30

Years of Innovation.Our History:

30 Years of Innovation.Our History:

1995

Rick Ridley launches DSE with the vision of creating an engineering-based, technical manufacturing company that leverages new technologies. During its early years, DSE designs and manufacturers white-box PCs, networks servers, RAID systems and specialized HVAC controllers.

1998

DSE releases its first display-based product, launching the company into the marine, food & beverage, agriculture, and mobile vehicle industries.

2004

The debut of the AWM 8.4” rugged touch screen display marks DSE’s entry into the open-pit mining sector.

2005

DSE releases an Electronic Flight Bag system utilizing its AWM display and Rugged Mobile Computer. This tool allows commercial pilots to digitally interface documentation, such as operation manuals and navigational charts while computing calculations for in-flight operations—all via a touch screen interface.

2006

DSE designs its first video decode/encoding PCBA, enabling greater control, flexibility and customization for display products in order to meet customer requirements.

2007

DSE marks its 10,000th mining installation following the wide adoption of AWM displays in haul trucks among leading global natural resource extractors.

2007

DSE achieves its first AS9100 QMS Registration, the most stringent international quality management system requiring substantial record keeping and continual improvement.

2008

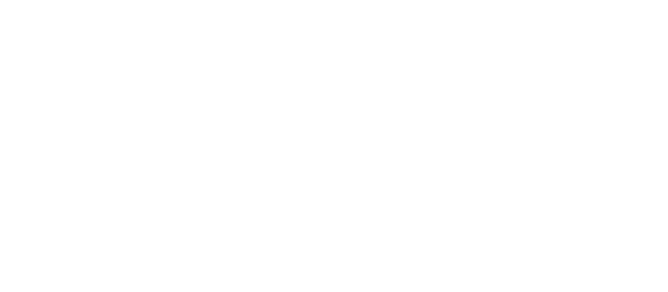

After over a decade of developing display technologies and specializing in ruggedization, DSE releases its first MIL-Spec product, the MSM2 Series. This rugged display line was designed for use in the Armed Security Vehicle, ASV, program and would later come to support THAAD Missile Launcher, Stryker, B1 Bomber, Amphibious Assault Vehicle, C130 and more.

2009

An MSM2 rugged display variant, the MSM212R is selected as part of the Stryker upgrade program; Iraq and Afghanistan Operations.

2010

DSE celebrates the grand opening of its state-of-the-art facility in Scottsdale, Arizona. The building and its layout were designed specifically to suite DSE’s manufacturing needs and to enable future expansion of production capabilities.

2011

The AWM NVIS display reaches its 500th MRAP Buffalo installation, a program helping allied forces to identify and detonate IEDs during the Afghanistan and Iraq conflicts.

2012

DSE kicks off 2012 with a series of key product launches, including its first high definition display unit, the HDRM and the expansion into digital video input configurations, including HDMI and HD-SDI.

2015

DSE expands its product offering to include embedded Digital Video Recorder (DVR) capabilities, starting first with the PSM DVR. DSE would continue developing custom DVR solutions for mission-specific aerospace and defense programs.

2018

FHDRM is released, offering a Full HD 1920×1080 LCD in addition to low power consumption, a high brightness backlight, and an ultra-thin form factor. Quickly becoming one of DSE’s signature products, the FHDRM proved its rugged performance through adherence to MIL-STDs 810, 461, 1275, 704, plus IP67 and DO-160.

2019

DSE releases the ALPHA mission computer, a rugged solution including the latest Quad Core 7th Generation Intel i7 processor, ATOM and ARM based CPUs. This industrial powerhouse would continue to log millions of operational hours on haul trucks, fracking trucks and excavators.

2021

DSE releases a new Linux-based network smart display system for its customers.

2023

DSE unveils its all-new Surface Mount Technology (SMT) production line. From solder paste printing to robotic placement of components, reflow soldering and inspection – DSE is able to manufacture printed circuit board assemblies with efficiency and flexibility

Our Facility

Full Production Line

Guided by the industry-leading AS9100 QMS, DSE's approach to building products ensures end-to-end configuration management, consistent outputs and an organizational focus on quality assurance.

Configuration Management

Our fully integrated configuration management platform allows for seamless connectivity through the product development and manufacturing process in order to deliver unmatched traceability and quality.

In-House Validation

DSE is equipped to perform Environmental Stress Screening (ESS) including temperature, vibration, submersion, impact and much more. Whether performing first article or component validation, DSE's ESS capabilities verify products meet program specifications.