From Specification to Production: Developing Custom Solutions

[Blog] From Specification to Production: Developing Custom Solutions

Over the last 25 years, Digital Systems Engineering has built a reputation as a design-build manufacturer serving the defense, industrial and manufacturing industries with quality, American-made rugged electronics. Our products have withstood extreme environments in applications ranging from military aircraft to the largest mining haul trucks, marine vessels, fast food kitchens and farm equipment in America’s heartland.

When two engineers with a passion for complex electrical systems founded DSE in 1995, they understood the importance of letting program opportunities drive technology and product development. That understanding set the foundation for DSE’s emergence as a design-build manufacturer with an inherent interest and core competency of engineering.

Today, DSE has dozens of product lines consisting of over 100 COTS configurations, including ruggedized computers, displays, video switches and network devices. Many of these products were born from requirements from OEM customers looking for a custom solution. We continue to develop unique products, taking our customer’s concepts through design, development, validation and ultimately production.

Keep reading to see how we’ve refined this process and leverage our deep product lines (including the AWM2, MSM2, FHDRM, and ALPHA) to deliver on our customer’s needs while reducing lead times and technical risk:

Specification:

During our initial consultative phase, we look to define, and possibly refine, program specifications, working closely with the customer as we consider accuracy, applicability and achievability. Our team of consultative program managers, expert systems engineers and software developers can identify the level of development needed by performing a gap analysis on the refined specifications and our existing product lines. With our modular approach to product design, this can come down to a straightforward printed circuit board modification for customer-driven inputs/outputs and an enclosure change. Other times, this can result in the need for an entirely custom product.

Proposal:

In the next phase, DSE proposes an economic approach to achieving the specified product by leveraging existing sub-assemblies and minimizing non-recurring expenses (NRE). If applicable, NRE supports activities such as tooling, setup charges, limited rate production, and vendor NRE. As a manufacturer, DSE is uniquely positioned to leverage its existing supplier relationships to secure competitive rates for custom and small run production.

Contract:

As product development continues, the contract stage provides customers with key documentation, including the development schedule, interface control drawings and supplier data requirements. DSE’s in-house team of technical writers work closely with our engineering team to define the function and care of the product, while our customers are provided with interface drawings, three-dimensional models and electrical pinouts. Our software development team also collaborates with the customer to identify the interaction between the new product and other onboard devices, such as cameras, switches and computers. This “all hands” approach, along with regular meetings to review progress and program requirements bring this stage together in preparation for production.

Environmental Validation:

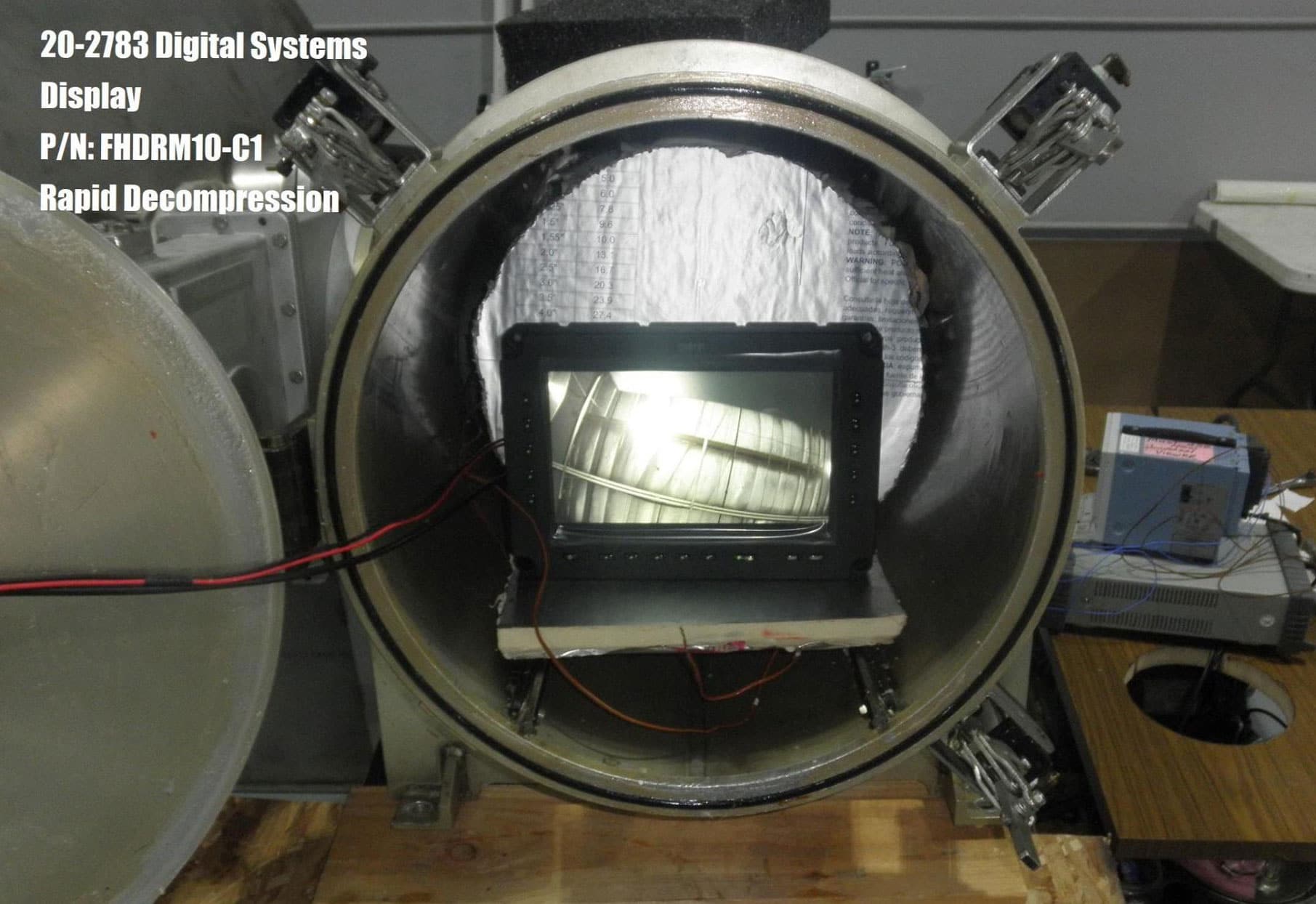

Before fielding any product, validating its design is one of the most important aspects of the development cycle. DSE is experienced in managing products through third-party testing laboratories, including most recently with an FHDRM variant developed for use in a fixed-wing aircraft program. In addition, DSE has in-house capabilities for vibration, temperature, submersion and general Acceptance Test Procedures, ensuring this stage of the process is handled with accuracy and expediency.

Production & Configuration Management:

Following delivery of first article units and successful validation testing, DSE looks to support the product through the life of the program. This process involves managing sub-assembly inventory, product life cycles, revision control, and control over processes such as assembly instructions, Acceptance Test Procedures, and calibration of equipment. DSE’s nimble manufacturing operation allows for an approximate throughput of 3,000 systems per month.

The process of developing a custom product brings with it a set of challenges in managing lead times, technical risk and supply chain management. Having a partner in this process that is an experienced design-build manufacturer that can leverage in-house expertise, proven product designs, and product life cycle is essential to ensuring program success. With decades of experience designing new and unique products based on customers’ defined specifications, DSE delivers quality products and processes that its partners rely on.

Have a question about our custom solutions or the product development process? Contact our team at sales@digitalsys.com to learn more.

Meet the FHDRM Rugged Display

Meet the FHDRM Rugged Display

Rugged MIL-SPEC Design

As a powerhouse of rugged design and operational performance, the FHDRM has quickly become one of Digital Systems Engineering’s signature products. It’s rugged MIL-SPEC design paired with powerful optical capabilities and diverse I/Os are a testament to DSE’s 25 years of experience designing and manufacturing innovative solutions for the defense and aerospace industries. Continue reading, or watch our video below to learn more about the FHDRM rugged display.

The FHDRM: Key Product Features

Full High Definition: FHDRM doesn’t compromise on quality; its 1920 x 1080 LCD screen delivers unmatched optical performance.

Diverse Digital and Analog Interfaces: The FHDRM supports the latest digital input technology including HD-SDI, HDMI, and DVI while also offering legacy analog inputs such as VGA, RS-170 and more.

MIL-STD Adherence: Extreme environments are no match for the FHDRM’s rugged design. With adherence to MIL-STDs 820, 461, 1275, 704, plus IP67 and DO-160, this rugged display meets even the most demanding environmental standards during critical missions.

Programmable Bezel Keys: With 15 programmable bezel keys, FHDRM allows for control of external systems and custom interfaces.

Customization: As a seasoned design-build manufacturer, DSE is experienced in bringing its clients’ visions and needs to production. Customizable FHDRM variants include CANBus, GPIO lines, and fully customizable RS422 command structures.

Field Tested: FHDRM is trusted by allied forces across the globe and has a proven track record of exceptional performance in C4ISR applications, combat helicopters and next generation ground vehicles.

Don’t just take our word for it. The FHDRM’s performance was recently validated in a third-party laboratory before being fielded for an Intelligence, Surveillance and Reconnaissance (ISR) application earlier this year. In an extensive series of procedures, the FHDRM demonstrated its capabilities under extreme conditions. Find the full article on our Knowledge Center here.

If you would like to learn more about the FHDRM, or any of our rugged displays and solutions, contact sales@digitalsys.com to speak with a member of our team.