Behind the Build: Hard Anodized Aluminum

Behind the Build: Hard Anodized Aluminum

Join DSE as we take you ‘Behind the Build’ to learn more about the processes that go into designing and building rugged electronics.

Hard anodized aluminum is a durable metal finish that can be found in applications ranging from race cars to consumer goods and even DSE’s rugged electronics. Many of DSE’s rugged displays, including the FHDRM, DLX and PTAC2, feature an enclosure made of milled aluminum with a hard anodized finish, which provides the strength and longevity needed in extreme environments.

Continue reading to learn more about hard anodized aluminum, and why it’s a clear choice for rugged applications in the defense, aerospace and mining worlds.

How Hard Anodization Works

This post-processing finish refers to the process of converting a deoxidized aluminum component into an oxide film. There are three primary types of anodization that refer to the thickness and application process. Types I and II are conventional methods that range in thickness from 0.0001” to 0.0006”. Type III, or Hard Coat Anodize, requires more stringent processing conditions which results in a harder and denser component. Hardcoat also ranges in thickness from 0.0005” to 0.0030”. All DSE products use the Type III Hard Coat Anodization process to achieve the maximum durability and strength required in rugged environments.

To begin the anodization process aluminum components first undergo a cleaning and rinsing process and are then placed in an electrolytic solution, such as sulfuric acid. A strong electrical charge is then applied, forcing negative ions to be attracted to the aluminum component which acts as an anode. As positive ions leave the surface of the aluminum part, oxygen ions combine with the aluminum atoms to complete the anodization process.

Why Choose Hard Anodized Aluminum?

Unlike plating or paint, the anodization process alters the aluminum substrate itself, resulting in a durable material that can then be sealed or painted. Through the anodization process the component becomes more resistant to corrosion, abrasion and general wear.

Anodized components also provide performance under extreme environmental conditions, withstanding shock and vibration better than their composite counterparts. Additionally, the combination of a milled aluminum enclosure with a hard anodized finish maintains the Faraday cage needed to meet the stringent requirements of EMI-461.

Not convinced yet? Besides resulting in a more durable component, choosing milled aluminum with a hard anodized finish can also result in a unit that is more scalable over time. When compared to a cast molded part, milled aluminum is a more cost-effective solution for low-volume needs. Its relatively low upfront development cost also allows for flexibility in design when approaching customized needs.

Hard anodized aluminum is a top-choice among the defense, aerospace and mining industries where components must deliver sustained performance under unforgiving environmental conditions. Through the anodization process, standard aluminum parts are transformed into durable components ready for field-use.

Thank you for going ‘Behind the Build’ with DSE in this first blog installation. Want to learn more about our hard anodized enclosures, rugged electronics or any other in our build-design process? Contact us to learn more.

From Specification to Production: Developing Custom Solutions

[Blog] From Specification to Production: Developing Custom Solutions

Over the last 25 years, Digital Systems Engineering has built a reputation as a design-build manufacturer serving the defense, industrial and manufacturing industries with quality, American-made rugged electronics. Our products have withstood extreme environments in applications ranging from military aircraft to the largest mining haul trucks, marine vessels, fast food kitchens and farm equipment in America’s heartland.

When two engineers with a passion for complex electrical systems founded DSE in 1995, they understood the importance of letting program opportunities drive technology and product development. That understanding set the foundation for DSE’s emergence as a design-build manufacturer with an inherent interest and core competency of engineering.

Today, DSE has dozens of product lines consisting of over 100 COTS configurations, including ruggedized computers, displays, video switches and network devices. Many of these products were born from requirements from OEM customers looking for a custom solution. We continue to develop unique products, taking our customer’s concepts through design, development, validation and ultimately production.

Keep reading to see how we’ve refined this process and leverage our deep product lines (including the AWM2, MSM2, FHDRM, and ALPHA) to deliver on our customer’s needs while reducing lead times and technical risk:

Specification:

During our initial consultative phase, we look to define, and possibly refine, program specifications, working closely with the customer as we consider accuracy, applicability and achievability. Our team of consultative program managers, expert systems engineers and software developers can identify the level of development needed by performing a gap analysis on the refined specifications and our existing product lines. With our modular approach to product design, this can come down to a straightforward printed circuit board modification for customer-driven inputs/outputs and an enclosure change. Other times, this can result in the need for an entirely custom product.

Proposal:

In the next phase, DSE proposes an economic approach to achieving the specified product by leveraging existing sub-assemblies and minimizing non-recurring expenses (NRE). If applicable, NRE supports activities such as tooling, setup charges, limited rate production, and vendor NRE. As a manufacturer, DSE is uniquely positioned to leverage its existing supplier relationships to secure competitive rates for custom and small run production.

Contract:

As product development continues, the contract stage provides customers with key documentation, including the development schedule, interface control drawings and supplier data requirements. DSE’s in-house team of technical writers work closely with our engineering team to define the function and care of the product, while our customers are provided with interface drawings, three-dimensional models and electrical pinouts. Our software development team also collaborates with the customer to identify the interaction between the new product and other onboard devices, such as cameras, switches and computers. This “all hands” approach, along with regular meetings to review progress and program requirements bring this stage together in preparation for production.

Environmental Validation:

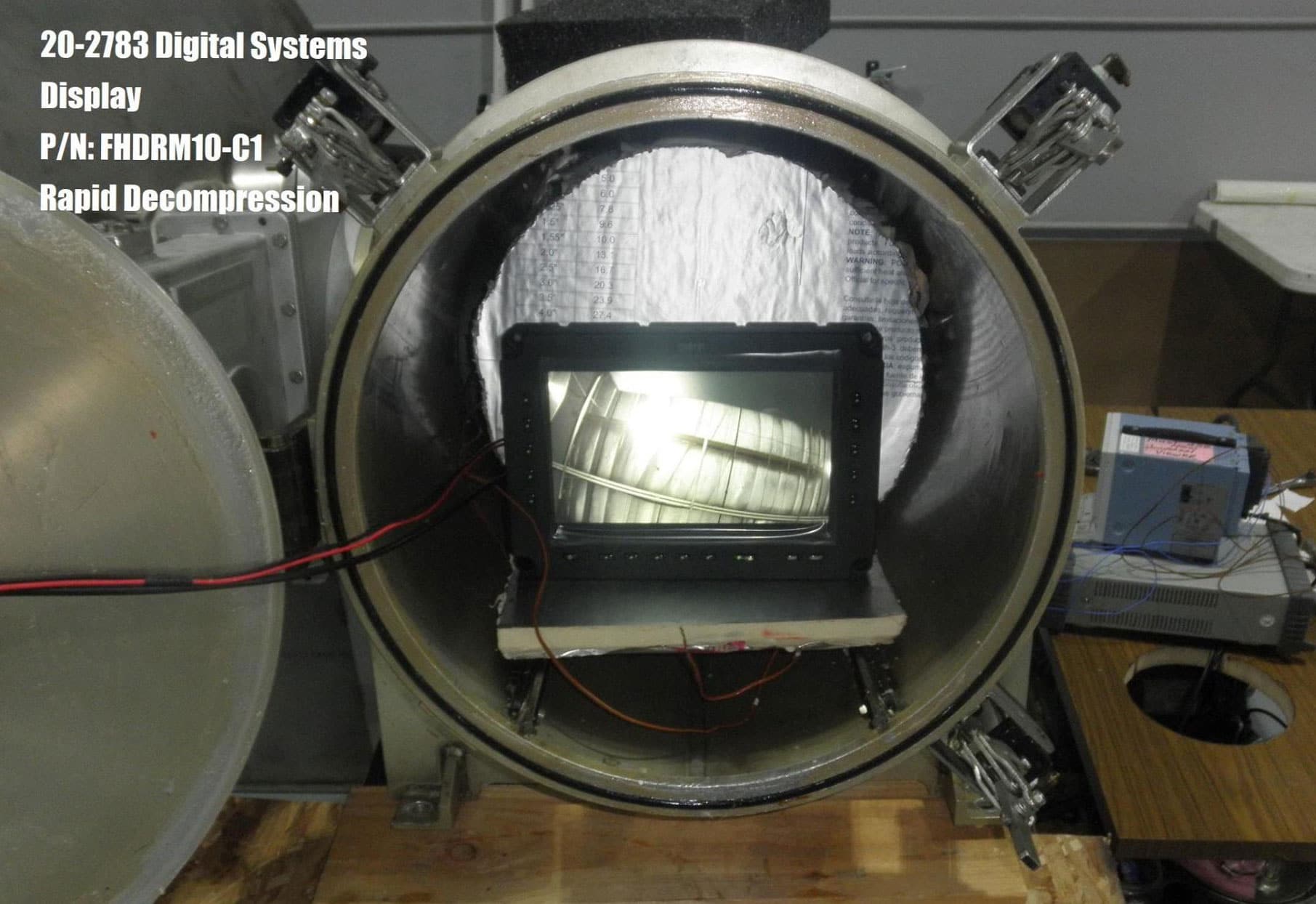

Before fielding any product, validating its design is one of the most important aspects of the development cycle. DSE is experienced in managing products through third-party testing laboratories, including most recently with an FHDRM variant developed for use in a fixed-wing aircraft program. In addition, DSE has in-house capabilities for vibration, temperature, submersion and general Acceptance Test Procedures, ensuring this stage of the process is handled with accuracy and expediency.

Production & Configuration Management:

Following delivery of first article units and successful validation testing, DSE looks to support the product through the life of the program. This process involves managing sub-assembly inventory, product life cycles, revision control, and control over processes such as assembly instructions, Acceptance Test Procedures, and calibration of equipment. DSE’s nimble manufacturing operation allows for an approximate throughput of 3,000 systems per month.

The process of developing a custom product brings with it a set of challenges in managing lead times, technical risk and supply chain management. Having a partner in this process that is an experienced design-build manufacturer that can leverage in-house expertise, proven product designs, and product life cycle is essential to ensuring program success. With decades of experience designing new and unique products based on customers’ defined specifications, DSE delivers quality products and processes that its partners rely on.

Have a question about our custom solutions or the product development process? Contact us to learn more.