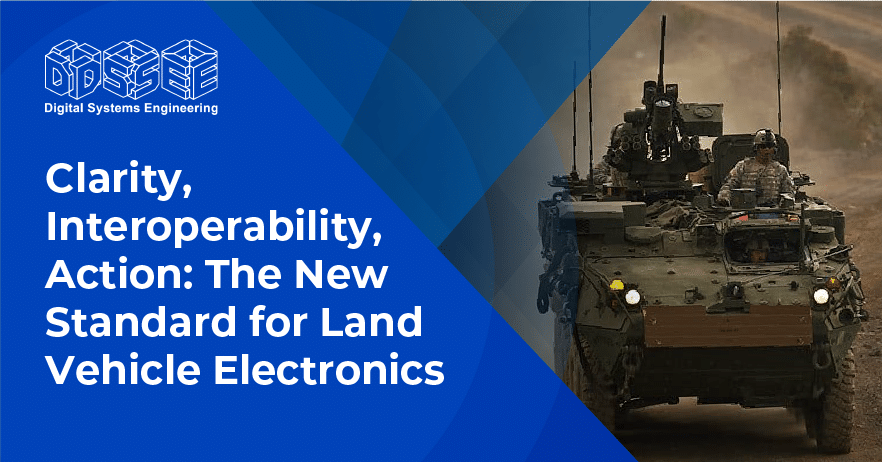

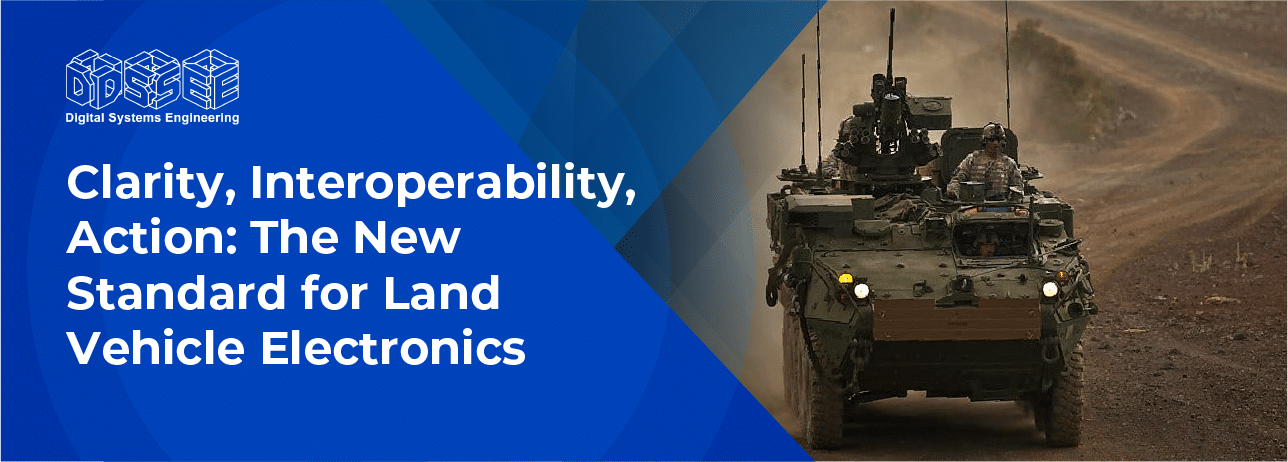

Clarity, Interoperability, Action: The New Standard for Land Vehicle Electronics

Clarity, Interoperability, Action: The New Standard for Land Vehicle Electronics

As modernization initiatives accelerate and the battlefield grows more complex, defense programs demand rugged electronics that not only endure but also enable. The next generation of land vehicle technology depends on systems that deliver clarity, interoperability, and real-time data integration—turning information into decisive action.

At Digital Systems Engineering (DSE), rugged design is only the beginning. With over 30 years of experience supporting leading land vehicle programs, DSE bridges the gap between legacy systems and next-generation platforms. Through modular, design-build engineering, we help integrators overcome complex challenges—from consolidating data sources and reducing cabling weight to optimizing form factors for confined crew stations.

As a proven partner in land vehicle modernization, DSE’s solutions have been integrated across a wide range of mission-critical platforms, enabling defense partners to enhance situational awareness and crew efficiency under demanding conditions. From driver-vision enhancement systems to high-definition rugged monitors, our technology is designed to deliver dependable performance in extreme environments where failure is not an option.

Our latest one-pager, Rugged Electronics for Next-Generation Land Vehicles, provides a concise overview of how these technologies are shaping the future of battlefield electronics. It highlights proven hardware integrated across key programs—including Abrams, Stryker, ACV, and MMPV—and illustrates how DSE’s products transform awareness into action through interoperability with vehicle systems.

Whether your team is modernizing vehicle electronics or seeking new ways to increase system performance and interoperability, this resource offers valuable insight into the solutions enabling mission success on today’s battlefield.

Continue reading Rugged Electronics for Next-Generation Land Vehicles to see how DSE is shaping the future of battlefield systems.

DSE Introduces PCAP: Precision Touch for Rugged Applications

DSE Introduces PCAP: Precision Touch for Rugged Applications

At Digital Systems Engineering (DSE), innovation is at the core of our business. From advanced digital inputs and outputs to high-definition LCDs, we consistently look for opportunities to integrate modern technological advancements in the rugged, MIL-Spec electronics space.

Over the past year, we’ve been integrating Projective Capacitive (PCAP) touch technology into our diverse catalog of rugged displays, including our flagship FHDRM line as well as a growing number of OEM-specific designs. These advancements bring improved user experience through added interactive features, as well as optical enhancements, all while maintaining the robust performance you would expect from DSE’s rugged displays.

What is PCAP technology?

PCAP technology is known as the gold standard in modern touch interfaces, and is widely known for its application in consumer electronics such as smartphones, tablets, gaming consoles and much more. PCAP touch screens operate by detecting changes in an electrostatic field. Below the surface of the screen, a series of intersecting rows and columns of electrodes form a uniform electrical field across the touch surface. When a conductive object, such as a finger, makes contact with the screen’s surface it disrupts the capacitance and the screen’s sensors precisely pinpoint the location of the touch point. This technology allows for the detection of multiple touch points at once, which gives the ability to perform actions such as pinch to zoom.

While this technology was originally developed with an eye toward the consumer space, PCAP is rapidly becoming the standard in mission-critical applications. Its enhanced touch accuracy and durability make PCAP touch technology an ideal solution for aerospace and defense, industrial and mining programs that require rugged performance.

Benefits of PCAP touch screen technology

In addition to the added touch accuracy that PCAP provides, it supplies users with the ability to tune sensitivity in order to customize the responsiveness of the display. This, paired with multi-touch support, contributes to a more robust user experience consistent with what we see in modern consumer electronics.

The benefits of PCAP touch technology don’t end with just the interface. In fact, with the integration of PCAP touch technology, DSE rugged displays have added optical enhancements such as reduced glare and reflectivity, plus superior direct sunlight readability. These features are ideal for outdoor and vehicle-mounted applications where extreme environments must be considered. Finally, PCAP continues to prove itself as a durable, reliable technology that is widely compatible among a diverse range of platforms.

Integration of PCAP technology in DSE displays

Integration of PCAP touch technology in any of DSE’s proven rugged displays first starts with optically bonding the touch sensors to the LCD screen. This process of applying the PCAP touch technology to our rugged displays isn’t much different from what you would see in the consumer electronics space. Optically bonding a PCAP touchscreen to the LCD’s faying surface effectively creates a single assembly that reduces reflectivity, eliminates a physical void, and strengthens the components. In industries that rely on durability and optical performance, such as industrial mining or even defense applications, this seamless application is critical.

Ready to Learn More?

If you’re looking for rugged touch screen solutions that combine cutting-edge PCAP performance with field-proven reliability, contact DSE today. Our engineering team is ready to help integrate PCAP touch into your next display system, whether you’re upgrading an existing platform or looking for a custom solution to meet your program specifications.